3D Scanning for Measurements of Transport Lines for Kiln Burner Feed in Cement Plant

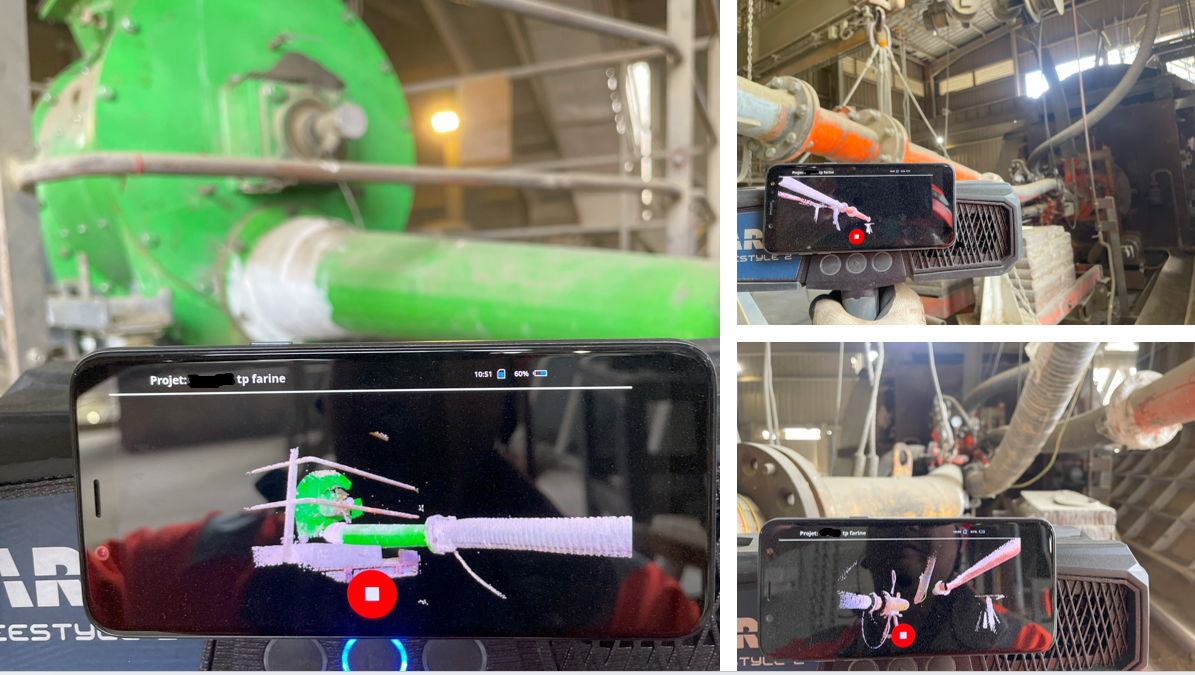

We visited a french cement plant with our handheld scanner in order to take 3D measurements of the feed lines to the rotary kiln burner.

The burner is powered by various fuels (sawdust, waste, and coal). These fuels are pneumatically transported to the burner at high flow rates and speeds, causing significant wear and tear (limited lifespan of the pipes and rubber hoses).

This wear lead to material losses, production stoppages, and significant maintenance costs.

To improve the reliability of these areas and in the absence of existing plans, our 3D scanner allows us to take 3D measurements to create a new layout with our reinforced solutions.

We therefore propose to our client:

✅ A reverse engineering of the three lines (defining the passage of the three lines according to the space constraints)

✅ A budget offer for the supply of reinforced pipes with ceramic and alumina hoses, ensuring extended lifespans

✅ The supply and supervision of the on-site installation of the new pneumatic transport lines

Feel free to contact us for any related project in your industrial site !